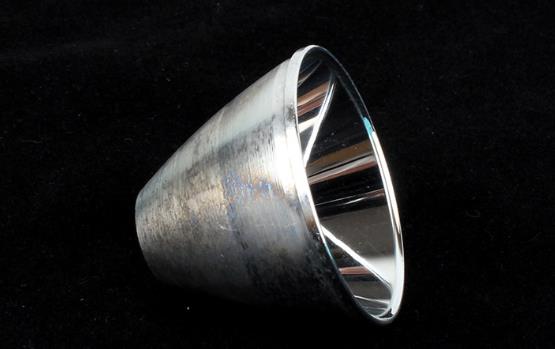

Ngokuvamile, amandla okukhanya avela emthonjeni wokukhanya azokhipha inkomba engu-360°. Ukuze kusetshenziswe ngempumelelo amandla okukhanya alinganiselwe, isibani singakwazi ukulawula ibanga lokukhanya nendawo yokukhanya yendawo enkulu yokukhanya ngesibonisi sokukhanya. Inkomishi ekhanyayo iyisibonisi esisebenzisa i-COB njengomthombo wokukhanya futhi sidinga ukukhanya okukude. Ngokuvamile kuwuhlobo lwenkomishi, oluvame ukwaziwa ngokuthi inkomishi ekhanyayo

Izinto zenkomishi ezibonisayo kanye nezinzuzo kanye nokubi

I-Reflector ingaba inkomishi ekhanyayo yensimbi futhiI-Plastiki Reflector,okuhle nokubi okuyinhloko kukhonjisiwe kuthebula elilandelayo:

| Okubalulekile | Izindleko | Ukunemba kwe-Optical | Ukumelana Nokushisa | Ukushisa Ukushisa | Ukumelana ne-Deformation | Ukuvumelana |

| Insimbi | Phansi | Phansi | Phezulu | Kuhle | Phansi | Phansi |

| Ipulasitiki | Phezulu | Phezulu | Maphakathi | Maphakathi | Phezulu | Phezulu |

I-1, i-Metal Refletor: ukunyathela, inqubo yokupholisha ukuqedela, inkumbulo yokuguqulwa, izinzuzo zezindleko eziphansi, ukumelana nezinga lokushisa, okuvame ukusetshenziswa ezidingweni zokukhanyisa ezisezingeni eliphansi zezibani nezibani.

2. I-Reflector yePlastiki: ukuqedwa kwe-demold, ukunemba okuphezulu kwe-optical, inkumbulo engabonakali, izindleko ezilinganiselwe, ezivame ukusetshenziswa emazingeni okushisa aziphezulu ezidingweni zokukhanyisa ezisezingeni eliphezulu zezibani nezibani.

Umehluko wezinga lokubonisa:

Ukusebenza kahle kwesendlalelo sokumboza okubonisa ukukhanya okubonakalayo. I-vacuum plating ye-muon iphakeme kakhulu, i-vacuum plating ye-aluminium ingeyesibili, i-anodic oxidation iphansi kakhulu.

I-1, i-Vacuum aluminium Plating: isetshenziswa kupulasitiki okumelana nezinga lokushisa nenkomishi yensimbi ekhanyayo. Izinga le-reflective liphezulu, kuyinqubo eyinhloko yokuhlanganisa izimoto kanye nezibani eziningi eziphezulu nezibani. Kunezinhlobo ezimbili zokwelashwa kwe-vacuum aluminium plating, eyodwa i-UV, ingaphumelela ukuhlolwa kwesifutho sikasawoti, i-aluminium plating engaphezulu akulula ukuwa, ukubonakaliswa okulinganiselwe kuka-89%. Enye akuyona i-UV. I-aluminium plating yangaphezulu ingase ithathe unyaka noma emibili ukuwa, ayifanele ukusetshenziswa emadolobheni asogwini. Ukubonakaliswa okulinganiselwe kungu-93%.

2, i-anodic oxidation: isetshenziswa enkomishini yensimbi. Izinga lokubonisa elisebenzayo lingaphansi kwesigamu se-vacuum aluminium plating. Inzuzo ayesabi i-ultraviolet, umonakalo we-infrared, futhi ingahlanzwa ngisho namanzi.

3, Amabhizinisi athekelisa, inkomishi yepulasitiki ingadlula imithetho yokuphepha, inkomishi ye-aluminium ayikwazi ukudlula imithetho yokuphepha.

4. Ngenxa yokuthi ukuvumelana kwezinkomishi ze-aluminium kuphansi, uma wenza i-100PCS yemikhiqizo, amabala angase ahluke kwelinye. Ngenxa yokuthi izinkomishi zepulasitiki zenziwa ukubunjwa komjovo wesikhathi esisodwa, ukuvumelana kuphezulu. Iphethini yokukhanya iphelele.

5. Ukubukeka kwenkomishi ye-aluminium kuphansi kakhulu, futhi ukubukeka kwe-vacuum aluminium plating kufika ku-70%. Izindleko zokonga ukukhanya zanele ukukhokhela umehluko phakathi kwezinkomishi zepulasitiki ne-aluminium, futhi uma ukugeleza kwezibani kukhudlwana, izindleko ze-R&D zingancishiswa zibe ncane.

I-6, Ukubukeka kwesibonisi sepulasitiki kuhle kakhulu kunesibonisi sensimbi, imikhiqizo ephezulu.

Isikhathi sokuthumela: Aug-10-2022